Amazon

3P Fulfillment and Inventory Management: An Overview

At least for once we all have come across such a notification while making a purchase. Now be honest and tell me how often you circle back to that product to check whether it’s restocked or not? The ratio is really low. The end result? A missed sale opportunity. Statistics report that stockouts result in a 3% profit loss annually. Proper 3P inventory management and order fulfillment ensure that your customers never see ‘out of stock’ notifications and you won’t miss out on a single sale.

So, in this blog we’ll discuss 3P fulfillment and inventory management and turn the sales game for your business in your favour. From its importance to its working model, you’ll get to know about all the ins and outs of 3P management and managing inventory for 3P sellers.

Why Do Stockouts Hurt 3P Sellers Across Marketplaces?

Stockouts are a silent revenue killer. For third-party sellers, especially those selling on multiple marketplaces like Amazon, Walmart, eBay, or Bol.com, a single “Out of Stock” message can result in lost revenue, wasted ad spend, and declining seller metrics.

Unlike DTC stores, 3P sellers often compete for Buy Box visibility or ranking where being in stock is a requirement, not a bonus. The damage affects long-term customer retention, algorithmic rankings, and even your eligibility for fast-shipping badges on major platforms.

Stockouts result in:

- Missed sales and reduced revenue

- Lower platform search rankings

- Wasted marketing spend

- Negative seller performance metrics

To stay competitive, 3P sellers must ensure inventory management and order fulfillment are tightly integrated and automated wherever possible.

What Is 3P Fulfillment?

“A seller-first model where logistics are managed independently or through outsourced solutions”

3P fulfillment, short for third-party fulfillment, refers to the end-to-end logistics process handled by third-party sellers who operate on platforms they don’t own. Unlike first-party (1P) models, where sellers sell to the platform directly, 3P sellers are responsible for the storage, picking, packing, shipping, and customer service of their own products.

These sellers use marketplaces like:

- Walmart Marketplace

- eBay

- Bol.com

- Etsy

- Zalando

- Cdiscount

- Amazon (FBM/SFP, not 1P)

Depending on their volume and structure, 3P sellers either:

- Fulfill orders in-house (self-fulfillment)

- Use a 3PL partner (third-party logistics provider)

- Enroll in a marketplace-run fulfillment program like WFS or FBA

This flexibility gives sellers greater control over branding, shipping timelines, and inventory flow across various platforms.

What Is the Difference Between 1P and 3P Models?

Many brands start with 1P and transition to 3P to gain more operational control and higher profit margins. In the 1P model, marketplaces purchase inventory and resell it. In contrast, 3P sellers maintain ownership and list items directly to consumers. The table below will give you a better overview of how these two models differ from each other:

| Attribute | 1P Sellers | 3P Sellers |

| Sales Relationship | Sell products to the marketplace | Sell directly to customers |

| Control over Pricing | Limited (set by marketplace) | Full control |

| Inventory Ownership | Transfers to the platform | Retained by the seller |

| Fulfillment Approach | Marketplace handles fulfillment | Seller chooses fulfillment model |

As eCommerce evolves, most sellers prefer the 3P model due to greater control over inventory, customer experience, and scalability.

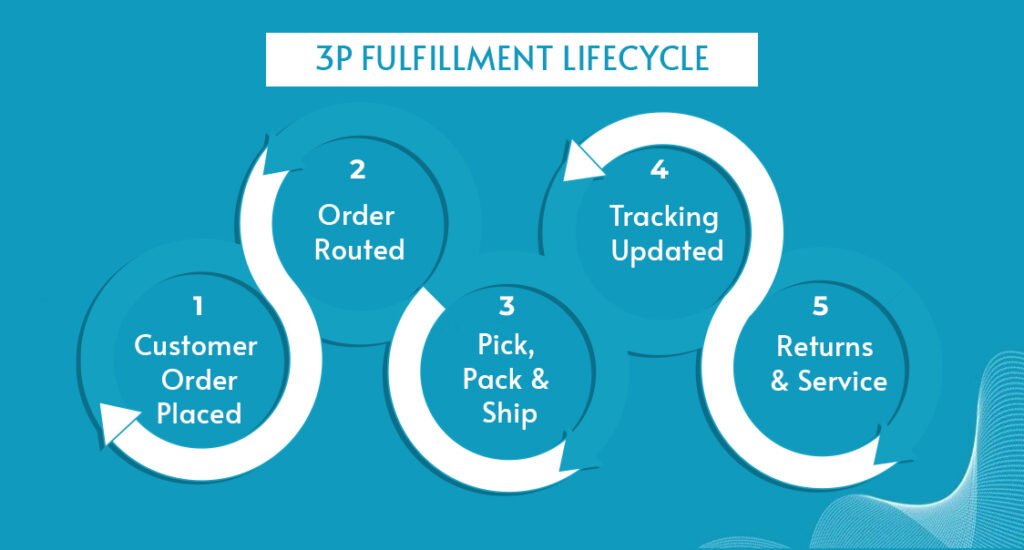

How Does the 3P Fulfillment Lifecycle Work?

Each marketplace may have its own platform-specific rules, but the 3P fulfillment process generally follows a universal sequence. Regardless of whether the seller uses FBM, WFS, or a 3PL, the steps remain similar.

- Customer places an order on the platform

- Order routes to the seller or logistics provider

- Product is picked, packed, and shipped

- Tracking is uploaded automatically

- Returns and customer service are handled per policy

This lifecycle tells how important it is to have reliable logistics systems, fulfillment inventory management software, and channel-specific rules to ensure smooth operations.

What Are the Main Fulfillment Models for 3P Sellers?

There is no one-size-fits-all model. Each fulfillment method has trade-offs in terms of cost, speed, control, and complexity.

| Fulfillment Model | Description | Platform Used On |

| Merchant Fulfilled | Seller handles logistics internally | All Platforms |

| 3PL Fulfillment | Third-party logistics partner manages inventory + shipping | All Platforms |

| Marketplace Fulfillment | Platform handles storage + shipping (e.g. WFS, FBA, Zalando) | Amazon, Walmart, Zalando, Bol.com |

| Hybrid Fulfillment | Combination of in-house + outsourced or marketplace fulfillment | Advanced multichannel sellers |

For high-growth sellers, hybrid fulfillment offers the best balance between cost and agility.

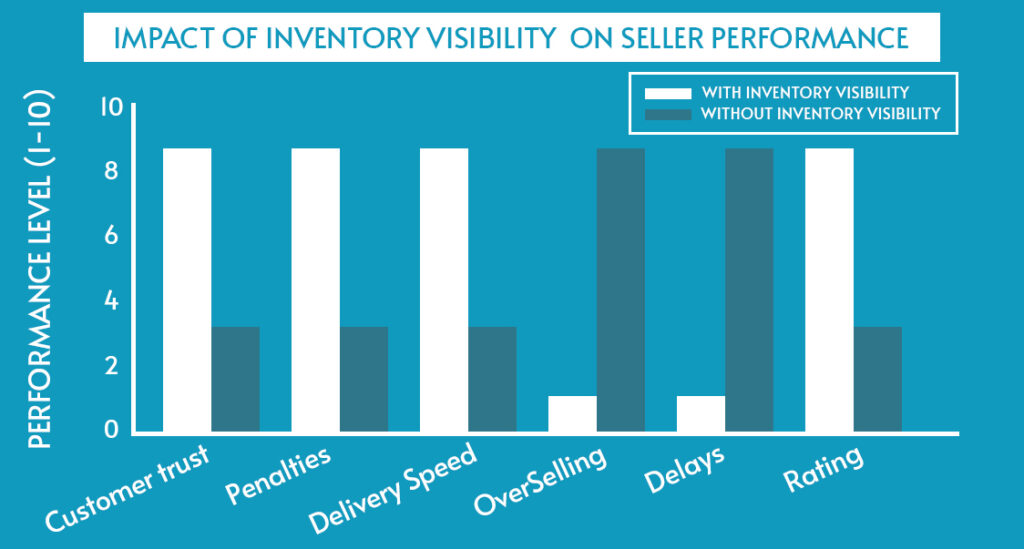

Why Is Inventory Visibility Critical for 3P Fulfillment?

Inventory visibility refers to knowing exactly what stock is available, where it’s stored, and how quickly it can be fulfilled. Without it, sellers face overselling, delayed shipping, and loss of customer trust.

Effective inventory management for 3P sellers includes:

- Real-time stock sync across channels

- Multi-warehouse visibility

- Stockout prevention using demand triggers

- Fulfillment routing based on proximity

A lack of inventory visibility can result in duplicate orders, late shipments, canceled listings, and performance penalties across multiple platforms.

How Do Fulfillment Decisions Affect Inventory Management?

Your logistics choices influence stock levels, reorder timing, and cash flow cycles

Inventory and fulfillment are interdependent. The fulfillment model you choose affects how and when inventory is ordered, stored, and moved. Want to see how? Let’s head over to a quick overview:

| Fulfillment Type | Inventory Impact |

| Marketplace Fulfillment | Must pre-stock fulfillment centers (FCs) |

| FBM/Direct Ship | Must track SKU velocity to avoid overselling |

| 3PL Fulfillment | Requires integration and live stock updates |

If you’re using multiple models, you must need to coordinate or else you have to deal with stock duplication or misaligned shipments.

Remember,

Delays in sync = Delays in delivery.

What Are the Challenges in Managing Inventory for 3P Sellers?

Whether you’re selling 10 SKUs or 10,000, inventory complexity increases as you expand across platforms. Manual processes simply don’t scale.

Challenges include:

- Stock sync issues across multiple platforms

- Demand forecasting errors during peak periods

- Manual inventory tracking via spreadsheets

- Multi-channel confusion (Amazon, Walmart, Shopify, etc.)

- Ad spend misalignment with low inventory SKUs

Inventory fulfillment needs to be automated, accurate, and intelligent especially if you are operating on performance-driven marketplaces.

What Is Inventory Fulfillment?

Inventory fulfillment is the mutual point where inventory management and logistics meet. When done right, it enables you to fulfill faster, avoid overselling, and reduce holding costs. Treating these as isolated processes leads to breakdowns.

Inventory fulfillment allows 3P sellers to:

- Reduce fulfillment delays

- Lower storage costs by optimizing reorder points

- Avoid overstocking slow-moving SKUs

- Meet marketplace SLAs (e.g., 2-day shipping on Walmart)

Which Inventory Management Solutions and Fulfillment Automation Tools Work Best?

Once order volume exceeds 5–10 per day, automation is not optional. You have to get your hands on it to streamline the operations for fulfillment and inventory management. Below is the list of tools that can help you stay on the top of inventory management and order fulfillment.

Inventory Management Software for 3P Sellers

| Tool | Use Case |

| Skubana | Cross-channel inventory + order management |

| SoStocked | Forecasting + restocking (ideal for Amazon sellers) |

| Sellerboard | Profit analytics + inventory forecasting |

| Restock Pro | FBA-focused stock planning + supplier tracking |

| Cin7 | ERP-level inventory + fulfillment tracking |

Fulfillment Automation Solutions

| Tool | Capability |

| Deliverr | Fast shipping + 2-day badging on Walmart, Shopify |

| ShipBob | Distributed fulfillment centers across North America |

| Cahoot | Peer-to-peer fulfillment network |

| Easyship | Cross-border shipping automation |

With this tool stack in your hand for inventory fulfillment, you will come across less human errors, the fulfillment speed will be increased and your overall operational transparency will be improved as well.

What Best Practices Improve 3P Inventory Fulfillment?

Actionable strategies for optimizing your stock and shipping

When inventory and marketing are in sync, sellers avoid wasted spend and lost sales. These best practices help ensure your logistics and inventory teams move in unison.

Apply these strategies to align inventory and order fulfillment:

- Use buffer stock to protect against demand spikes

- Link marketing campaigns to inventory availability

- Reconcile stock weekly across all warehouses and platforms

- Forecast based on real sales data per channel

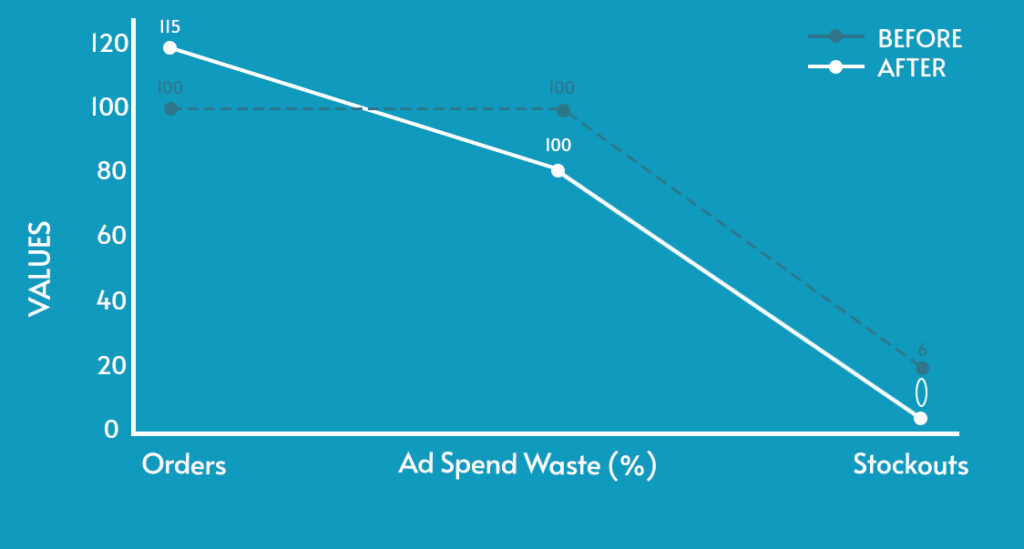

Case Example:

A 3P seller ran a holiday campaign across Amazon, Walmart, and Shopify. They:

- Analyzed Q4 sales trends for forecasting

- Sent inventory early to a 3PL and held safety stock

- Paused ads on low-stock SKUs

- Automated fulfillment with ShipBob and SoStocked

Result:

+15% order volume, -20% ad budget waste, 0 stockouts.

What Should Be in Your Fulfillment Inventory Checklist?

A monthly ops checklist to keep things on track

Avoid last-minute surprises and fulfillment breakdowns. Use this checklist as a recurring operational audit.

- time stock sync across all sales channels

- Forecasting accuracy based on last 12-month data

- Warehouse communication with logistics or 3PLs

- Reorder points based on safety stock + lead time

- Fulfillment KPIs tracked (late shipment, ODR, etc.)

- Marketing paused for low-inventory SKUs

- Returns workflows in place for each marketplace

Why Early Adoption of Inventory Tools Matters?

Most sellers wait too long to adopt inventory management software. But the truth is: if you don’t implement tools early, you’ll struggle when volume spikes. Early adoption lets you build a foundation that scales.

Benefits of adopting inventory management and fulfillment tools early:

- Improved cash flow via precise reordering

- Faster fulfillment with reduced human error

- Enhanced seller metrics on marketplaces

- Real-time decision making from synced data

Bottom Line

So, wrapping it up on the note that keeping all the things on your own table may sound a cost-effective option but that’s not true. While juggling between so many things, outsourcing the fulfillment and inventory management not only helps you focus on the things that really matter (e.g. product development, marketing, etc but also ensures that the fulfillment inventory management is being done rightly.

However, choosing the right inventory fulfillment services makes all the difference. However, if you’re looking for a similar one, Prime Retail Solution may be a right fit for you. With a portfolio of providing inventory and fulfillment solutions to 50+ brands, we assure you to take care of all the ins and outs of your inventory fulfillment. Want to discuss it further? Book a free consultation call right now.

FAQs

Q1. Why are stockouts such a big problem for 3P sellers?

Because marketplaces penalize sellers for going out of stock. It lowers rankings, wastes ad spend, hurts Buy Box chances, and can damage long-term customer loyalty.

Q2. How is 3P fulfillment different from 1P?

In 1P, the marketplace buys and resells your products, controlling price and fulfillment. In 3P, you keep full ownership, decide how to fulfill orders, and have more control over margins and customer experience.

Q3. What fulfillment approach should growing sellers choose?

There’s no one-size-fits-all, but many high-growth sellers succeed with a hybrid model, combining in-house fulfillment, 3PL partners, and marketplace programs to balance cost and speed.

Q4. Which tools are most helpful for inventory management?

Tools like SoStocked for forecasting, Skubana for cross-channel order management, and ShipBob or Deliverr for fast fulfillment help sellers streamline operations and stay competitive.

Q5. Why is it important to adopt inventory tools early?

Adopting tools before order volume spikes prevents errors, improves forecasting, speeds up fulfillment, and sets a strong foundation for scaling without chaos.

Share